Not known Details About Spot Welder

Wiki Article

Arc Welder Things To Know Before You Buy

Table of ContentsArc Welder Things To Know Before You BuySome Known Details About Cold Welding The smart Trick of Cold Welding That Nobody is DiscussingThe Best Guide To Cold Welding

CWIs remain in short supply in our area. The oil and gas industry has swallowed up a number of inspectors and nondestructive screening specialists because the pay in this market is far above what little service providers and great shops can pay. An inspector needs to inspect high-pressure equipment in the shop and after that witness the hydrostatic examination after setting up.

These towers typically are positioned on the highest tops in the area. Typically they can not be seen from below, because they are greater than the clouds (). The component of the tower that extends high right into the sky is produced before it's set up, and its welds are evaluated in the out-of-state stores that develop these frameworks.

Thankfully, no climbing is involved. A lot of the welds are fillet as well as flare groove welds () that connect stiffener plates to the cable retainers. These welds are made with the parts in position, which needs welding in all settings. There can be no problems since the welds are supporting 300- to 400-foot towers that need to stand up to very solid winds that are typical on mountaintops.

Unknown Facts About Mig Welder

Figure 5 Changing Job Landscape Much of the fab shop examination that we rely upon for many years has passed the wayside. There were a variety of shops that provided components and devices to coal-fired nuclear power plant right here as well as throughout the American Electric Power (AEP) system. As a result of expanded EPA guidelines, we have actually shed 5 coal-fired plants that these shops depended upon.

He or she has actually helped a really popular gas company in the north part of our state, so it should not be a fake accreditation. Generally, the pipe welds require radiography, which is not something we do. An Usual Demand One of our most usual task requests is for thickness screening.

I discover it hard to believe that a 50,000-gallon water container () is produced from -in. material. I recently examined the thickness on among these containers that originally was in. and also now is 3/32 in. in a number of areas near the base. This certain tank is on flat ground, however several of these maturing frameworks get on steep hillsides above housing advancements.

Arc Welder Fundamentals Explained

If one ought to fracture, it might clean out half of a village. Other Vital Assessments We are not a code state, but several area companies realize that wearing away air compressor receiver vessels might create tragic events. This is particularly real in the situation of an automobile filling station where individuals might be harmed.In the majority of instances, the proprietor is click site accountable as well as caring enough to accept my recommendation that the vessel be taken out of solution. One of the most frightening inspections that we do is on tramways in our state parks. These cable television cars commonly travel 500 to 600 feet above water or planet, and a breakdown can be disastrous.

The design company stated that the erector utilized inappropriate welding techniques, and also the erector stated that the welding product was visit not fix. On the various other hand, we uncovered that the erector did not use appropriate storage space and also managing approaches for the low-hydrogen electrodes that were used.

The Facts About Cold Welding Uncovered

A 3rd party was called in, and they agreed that we were not accountable for establishing the reason for the failing, however to find as well as report the failures. Before the case was completed in court, one flooring of the garage collapsed as well as the judge ruled in favor of the erector.Our CWI group is a little business in a small, mostly country state, but we still have numerous exciting and interesting things to do in the evaluation company. To us, our state truly is "Almost Paradise," "Wild and also Terrific," as well as "Some flux core welding Place Special" ().

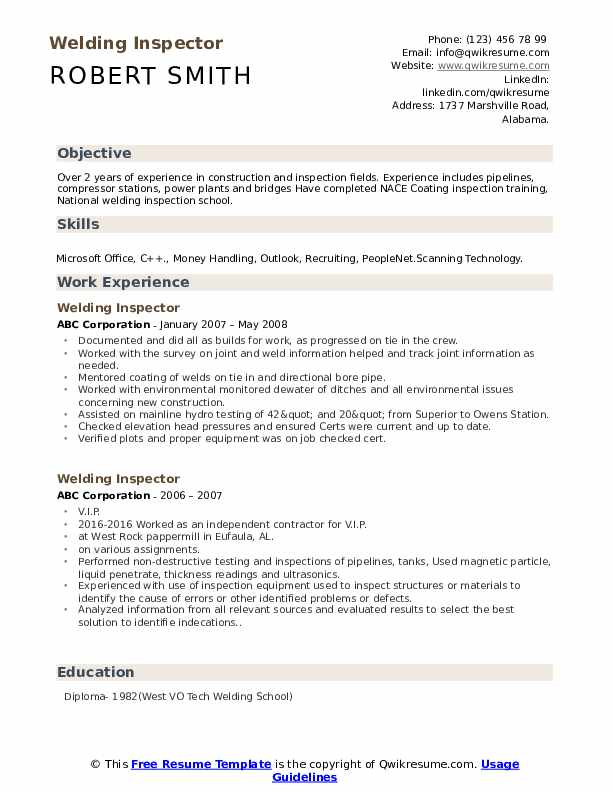

Relocating into welding inspector jobs is just one of one of the most usual occupation developments for Welders that are drawn in to the greater understanding side of welding - welding table. Depending on where in the world you are positioned, the procedure of ending up being a welding inspector will certainly be a little different, yet the globalization of design has presented a couple of internationally identified certifications as well as accreditations that qualifies you for a large variety of welding examiner jobs.

The Welder, Destiny Compass: Weekly e-zine Registration The Task of a Welding Examiner Basically, the duty of the welding assessor is to see to it that the design requirements for the weldment has been achieved. Because of this, it is considered a Quality assurance (QC) function. The welding examiner requires to understand what the demands are, and afterwards s/he demands to recognize if those requirements are being satisfied.

Report this wiki page